Additional Information

Use Custom Product to make a request for dimensions not shown.

Necks are furnished machined all over.

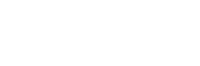

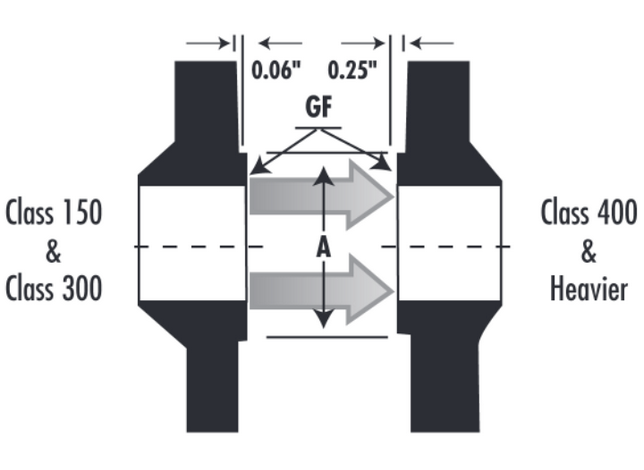

Unless otherwise specified, Class 300 Seamless Long Weld Necks will be furnished drilled and with a 0.06” raised face which is included in thickness “C” and Length “Y”.

Pressure-Temperature Ratings for Plant Piping and Pressure Vessel Flanges (Class 300)

| Metal Temperature F° | Pressureb (Pounds per Square Inch Gage) |

|---|---|

| 100 | 740 |

| 200 | 675 |

| 300 | 655 |

| 400 | 635 |

| 500 | 600 |

| 600 | 550 |

| 650 | 535 |

| 700 | 535 |

| 750 | 505 |

| 800 | 410 |

| 850 | 270 |

| 900 | 170 |

| 950 | 105 |

| 1000c | 50 |

a Based on the pressure ratings in ANSI B16.5 (1977), for use with flanges designed in accordance with the ASME Code or ANSI B31.1.

b Pressure-temperature ratings are based on material specifications ASTM A105 and A216 Grade WCB. Limitations on the use of these materials shall be in accordance with the applicable code.

c Maximum service temperature for the current class.

Dimensional Tolerances

| OUTSIDE DIAMETER* | When O.D. is 24” or less | ±1/16” |

| When O.D. is over 24” | ±1/8” | |

| INSIDE DIAMETER* | 10” and smaller | ±1/32” |

| 12” through 18” | ±1/16” | |

| 20” and larger | +1/8” -1/16” | |

| DIAMETER OF CONTACT FACE | 1/16” Raised Face | ±1/32” |

| 1/4” raised Face Tongue and Groove, or Male and Female | ±1/64” | |

| DIAMETER OF HUB AT POINT OF WELDING | 5” and smaller | +3/32”, -1/32” |

| 6” and larger | +5/32”, – 1/32” | |

| WELDING BEVEL STANDARDS | See drawings | |

| DIAMETER OF HUB AT BASE* | When Hub Base is 24” or less | ±1/16” |

| When Hub Base is over 24” | ±1/8” | |

| DRILLING | Bolt Circle | ±1/16” |

| Bolt hole spacing | ±1/32” | |

| ECCENTRICITY BOLT CIRCLE & FACING (with respect to Bore*) | 2 1/2” and smaller | 1/32” max |

| 3” and larger | 1/16” max | |

| LENGTH THRU HUB* | 10” and smaller | ±1/16” |

| 12” and larger | ±1/8” | |

| THICKNESS | 18” and smaller | +1/8” -0” |

| 20” and larger | +3/16” -0” | |

Back to top